Maximize Your Fiber Optic Performance: Comprehending Optical Fiber Size Analyser Technology

The efficiency of fiber optic systems is seriously affected by the precision of their size, an element commonly ignored in the quest of optimal signal stability. Comprehending the modern technology behind optical fibre diameter analysers exposes the intricate balance in between dimension accuracy and production quality.

Value of Optical Fiber Diameter

The size of optical fiber plays a critical role in identifying the performance and efficiency of interaction systems. Alternatively, smaller sized diameters tend to sustain less settings, which can enhance signal clarity and decrease crosstalk.

Moreover, understanding the size's implications can cause set you back financial savings by minimizing the requirement for signal amplification and repeaters in extensive networks (optical fibre diameter analyser). To conclude, the relevance of optical fibre size can not be overstated, as it straight impacts the general efficiency and dependability of modern-day communication systems

Exactly How Size Affects Signal Quality

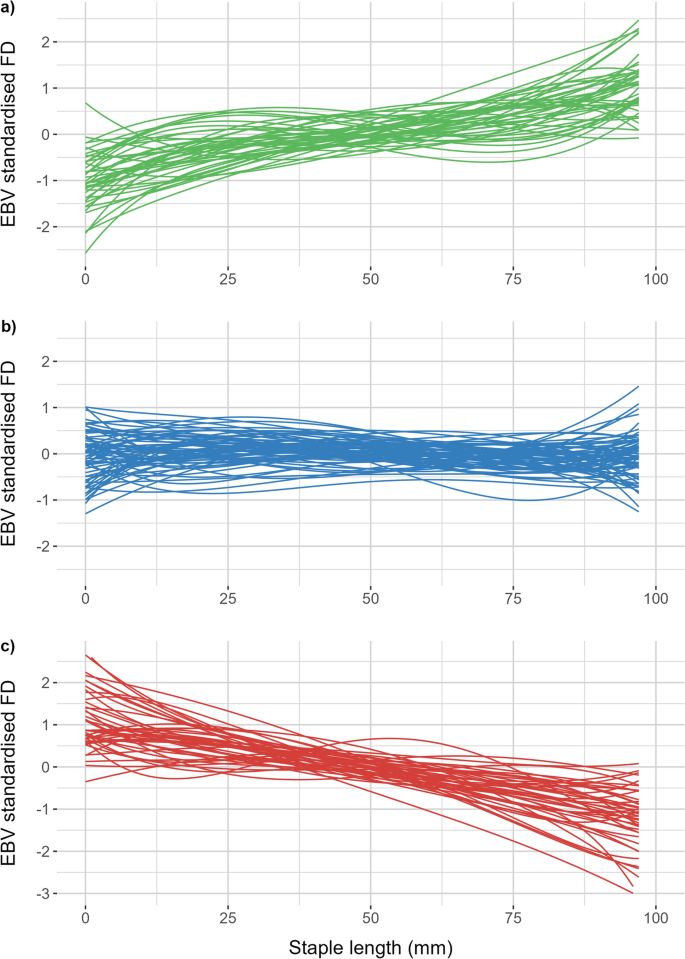

Signal top quality in optical fibre systems pivots significantly on the size of the fibre. The size affects several crucial specifications, including depletion, bandwidth, and modal diffusion. A smaller diameter can result in greater depletion rates, causing signal loss as light journeys with the fibre. This attenuation can jeopardize the stability of the transmitted information, causing a decrease in signal quality, especially over fars away.

Conversely, larger sizes normally enable boosted light capture and minimized modal diffusion, boosting signal clearness. In multimode fibers, a larger core diameter can sustain numerous light modes, yet it may likewise present intermodal diffusion, which can deteriorate signal high quality. Choosing the optimum fiber size is vital for attaining the desired performance in particular applications.

Furthermore, the communication between the fibre diameter and the wavelength of the light used plays an essential role in establishing the efficient transmission distance and total signal integrity. Therefore, recognizing just how fibre diameter influences signal quality is important for network designers and engineers aiming to maximize optical fibre systems for reliable, high-speed information transmission.

Review of Diameter Analyser Innovation

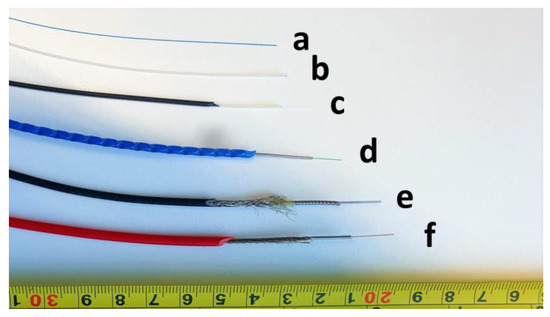

In several optical fibre manufacturing procedures, precise measurement of fiber size is necessary for guaranteeing consistent performance and top quality (optical fibre diameter analyser). Size analysers are advanced tools made to analyze the physical dimensions of optical fibres with high accuracy. They utilize advanced optical and laser innovations to gauge the size, ovality, and concentricity of the fibre, thus supplying critical information for top quality control

These analysers can operate in-line throughout the production procedure or as part of off-line testing protocols. In-line systems allow real-time monitoring, enabling suppliers to change criteria immediately, thereby maintaining ideal manufacturing problems. Off-line analysers, on the various other hand, give thorough evaluations of batches, making sure that any kind of inconsistencies from defined resistances are determined and attended to.

Size analysers significantly add to the decrease of issues in optical fibers, improving general item dependability. By consistently gauging vital specifications, these modern technologies promote conformity with sector criteria and specifications. As the need for high-performance optical fibers remains to climb, the function of size analysers becomes significantly essential in accomplishing the preferred high quality and efficiency criteria in fiber optic systems.

Secret Functions of Fibre Size Analysers

Although various versions of fiber diameter analysers exist, they frequently share several vital attributes that improve their performance and dependability. One of the most substantial functions is high-resolution dimension capacities, which make certain accurate size readings, important for keeping top quality control in fibre manufacturing. Additionally, numerous analysers include advanced optical sensing units created to spot minute variants in fibre size, hence offering vital information for process optimization.

One more crucial feature is real-time tracking, permitting operators to get immediate feedback on fibre size throughout the production process (optical fibre diameter analyser). This capacity facilitates Discover More quick adjustments and reduces the likelihood of problems. Lots of analysers also come geared up with straightforward user interfaces, enabling drivers to conveniently browse via setups and information outputs

Furthermore, robust information storage and evaluation functionalities are essential for tracking historic performance patterns and making sure compliance with industry standards. Some models even supply connectivity options for integration right into existing manufacturing control systems, enhancing total operational effectiveness. Last but not least, mobile and portable styles enable versatile release within manufacturing environments, making certain that quality guarantee processes are seamless and effective. These features jointly add to the effectiveness of fibre diameter analysers in enhancing fibre optic performance.

Ideal Practices for Fibre Optimization

First, normal calibration of optical fibre size analysers is crucial. This makes sure precise dimensions and lessens prospective disparities that can influence performance. Next off, maintaining a clean workplace is vital; dust and contaminants can result in indicate degradation.

Additionally, it is essential to choose fibres that satisfy certain application demands. This includes examining variables such as depletion, bandwidth, and ecological conditions. Appropriate installation techniques should additionally be stuck to, consisting of staying clear of sharp bends and extreme tension, which can compromise fibre integrity.

Moreover, using innovative monitoring systems can help with real-time performance evaluations, allowing timely identification of problems. Normal testing and maintenance need to be carried out to ensure that fibres stay within optimal operational parameters.

Last but not least, training employees on the most up to date fiber optimization technologies and methods will certainly improve their capacity to carry out efficient methods. By following these finest practices, companies can significantly boost the efficiency and life expectancy of their optical fiber systems, making certain efficient interaction and data transfer.

Conclusion

In conclusion, the combination of optical fibre diameter analyser modern technology is critical for making best use of fiber optic performance. By making sure exact measurements of fiber measurements, these analysers considerably enhance signal high quality and decrease losses throughout data transmission. Normal calibration and upkeep of the analysers are crucial to maintain optimal efficiency and compliance with market standards. Inevitably, the application of this technology promotes enhanced information transmission rates and reinforces signal integrity, adding to the overall performance of fiber optic systems.

Signal top quality in optical fibre systems hinges substantially on the size of the fiber.In many optical fibre production processes, exact dimension of fiber diameter is important for making certain consistent efficiency and top quality. As the demand for high-performance optical fibers proceeds to climb, the role of size analysers comes to be increasingly important in attaining the desired high site web quality and efficiency criteria in fiber optic systems.

These functions jointly contribute to the efficiency of fiber diameter analysers in enhancing fiber optic performance.

In final site link thought, the assimilation of optical fibre diameter analyser technology is important for making the most of fibre optic efficiency.

Comments on “Key Factors When Evaluating an Optical Fibre Diameter Analyser”